Details

Rated power operation the maximumtemperature of the battery is less than 40℃ EMS, hybrid inverter and BMS integrated technology,power supply redundancy design, support black startfunction, grid operation, etc Suitable for high-rate cyclic

Description

| Model | GE-F60 |

| System Specification | |

| Model | GE-F60-V1 |

| AC Output Frequency and Voltage | 50/60Hz; 3L/N/PE 220/380, 230/400Vac |

| Grid Type | Three phase |

| Energy Configuration (kWh) | 61.4 |

| Dimension (W x D x H,mm) | 735x1050x2250(no contain inverter) |

| Weight Appr. (kg) | 950(battery)+80(inverter) |

| AC Output Rated Current (A) | 75.8 |

| Battery Operating Voltage (V) | 500 ~ 700 |

| Max. charging/discharging efficiency | 91% |

| Battery Chemistry | LiFePO4 |

| IP Rating of Enclosure | IP55 |

| Installation Style | Floor-Mounted |

| Warranty | 10 years |

| Inverter Technical Specification | |

| Max. PV Input Power (W) | 65000 |

| Max. PV Input Current (A) | 36+36+36+36 |

| Rated PV Input Voltage (Vdc) | 600 |

| Start Up DC Voltage (Vdc) | 180 |

| MPPT Voltage Range (Vdc) | 150-850 |

| Max. PV Short-circuit Current (A) | 55+55+55+55 |

| Number of MPPT | 4 |

| Peak Power (off grid) | 1.5 time of rated power, 10s |

| Power Factor | 0.8 leading to 0.8 lagging |

| THD | <3% |

| DC injection current (mA) | <0.5%ln |

| Display | LCD |

| Operating Temperature Range (℃) | -40~60( >45℃ derating) |

| Relative Humidity | 15% ~ 85% (No Condensing) |

| Dimension (W x D x H, mm) | 527x294x894 |

| Inverter Communication | CAN, RS485, WIFI, ETH |

| Max. Efficiency | 97.6% |

| MPPT Efficiency | 99.9% |

| Battery Technical Specification | |

| Battery Module Nominal Voltage (V) | 51.2 |

| Battery Module Energy (kWh) | 5.12 |

| BMS Communication | CAN |

| Battery Module Dimension(W*D*H mm) | 440x570x133 |

| Battery Module Weight (kg) | 44 |

| Operating Temperature Range | Charge: 0~55℃ / Discharge: -20℃~55℃ |

| Cycle Life | ≥6000(@25℃±2℃,0.5C/0.5C,70%EOL) |

| Battery Module Certification | CE, IEC62619, IEC62040, UN38.3 |

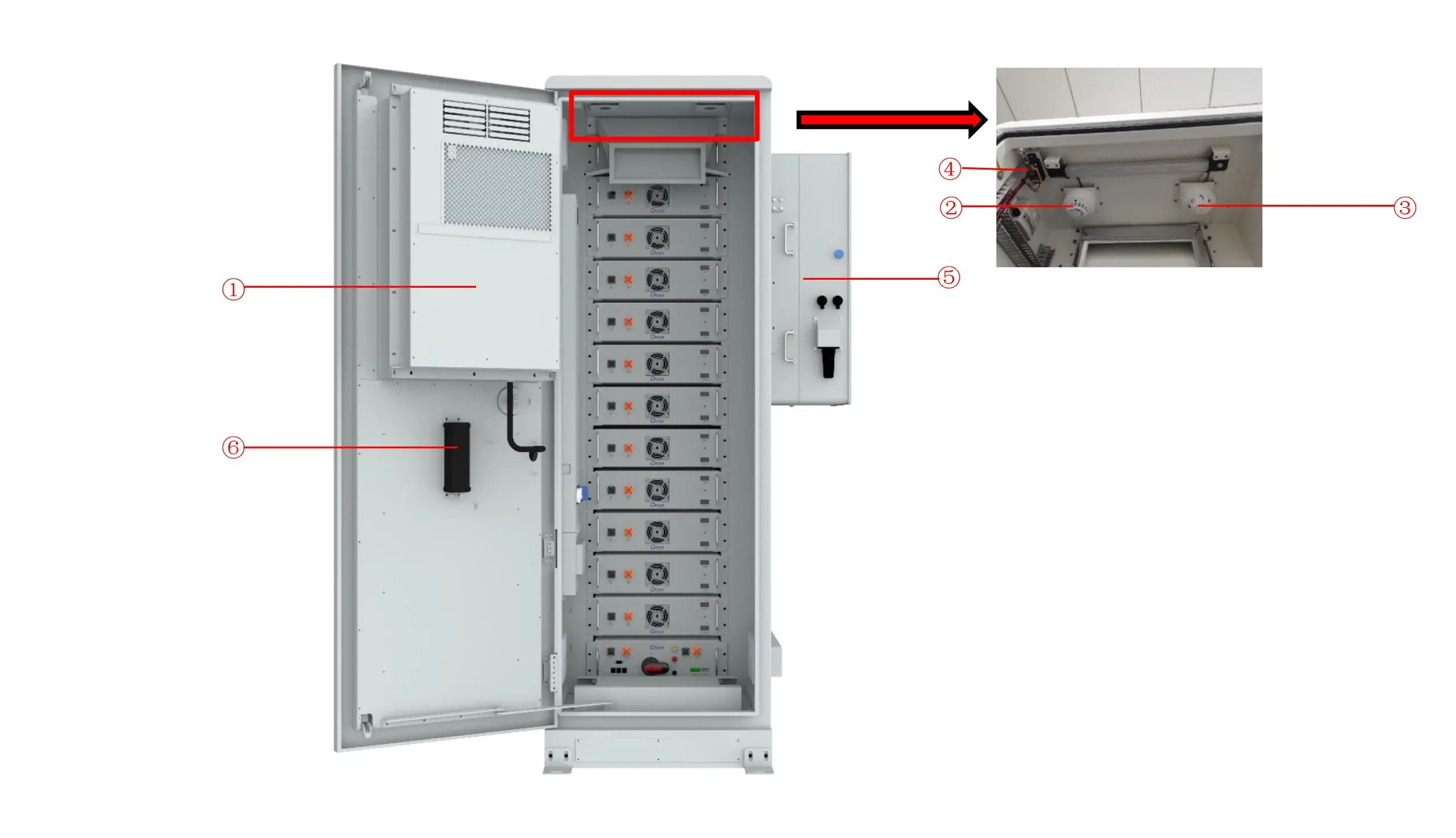

| ①Air conditioner cooling | g the ESS system |

| e detector |

A device used to detect smoke in a fire and sound an alarm when smoke is detected. |

| ③Heat detector |

A device used to measure temperature and sound an alarm if it detects excessive temperature. |

| ④Travel switch | Check whether the ESS system door is closed. |

| ⑤Inverter |

A device that converts direct current generated by a battery into alternating current. |

| ⑥Aerosol fire extinguishing device when |

n the ESS is detected to be on fire, aerosol is emitted to extinguish the fire. |

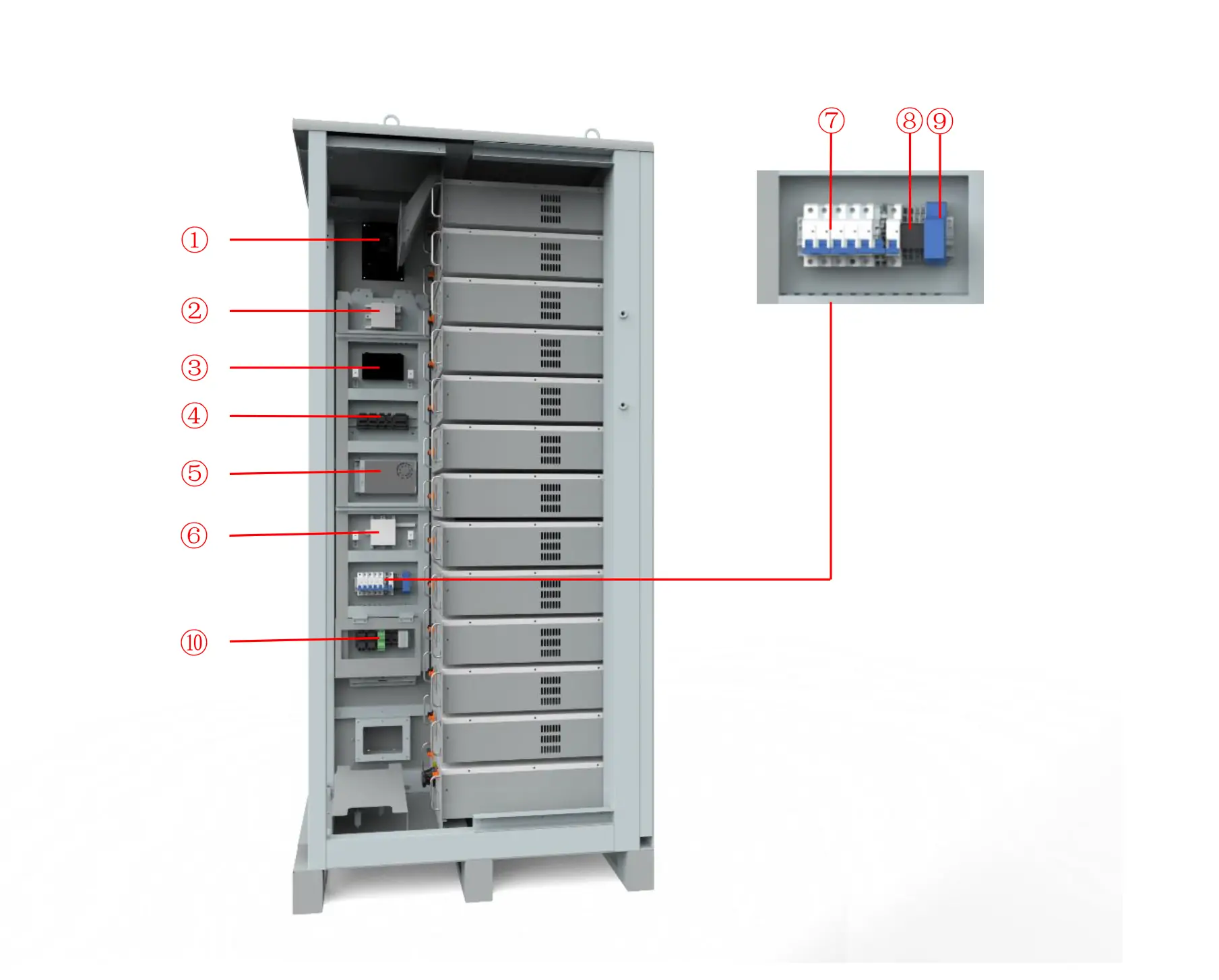

| ①Fan | Emission of combustible gas |

| ②Combustible gas sensor | Detect combustible gases |

| ③Serial relay | Control system |

| ④Terminal line | For connecting cables |

| ⑤Switching Mode Power Supply | Power source |

| ⑥Temperature and humidity sensor | Used to measure ambient temperature and humidity |

| ⑦Miniature circuit breaker | Controlled power-on and power-off |

| ⑧Relay | Automatic regulation, safety protection, conversion circuit |

| ⑨Water immersion sensor | Check the ESS for water leakage |

| ⑩Terminal line | Connect external cables |

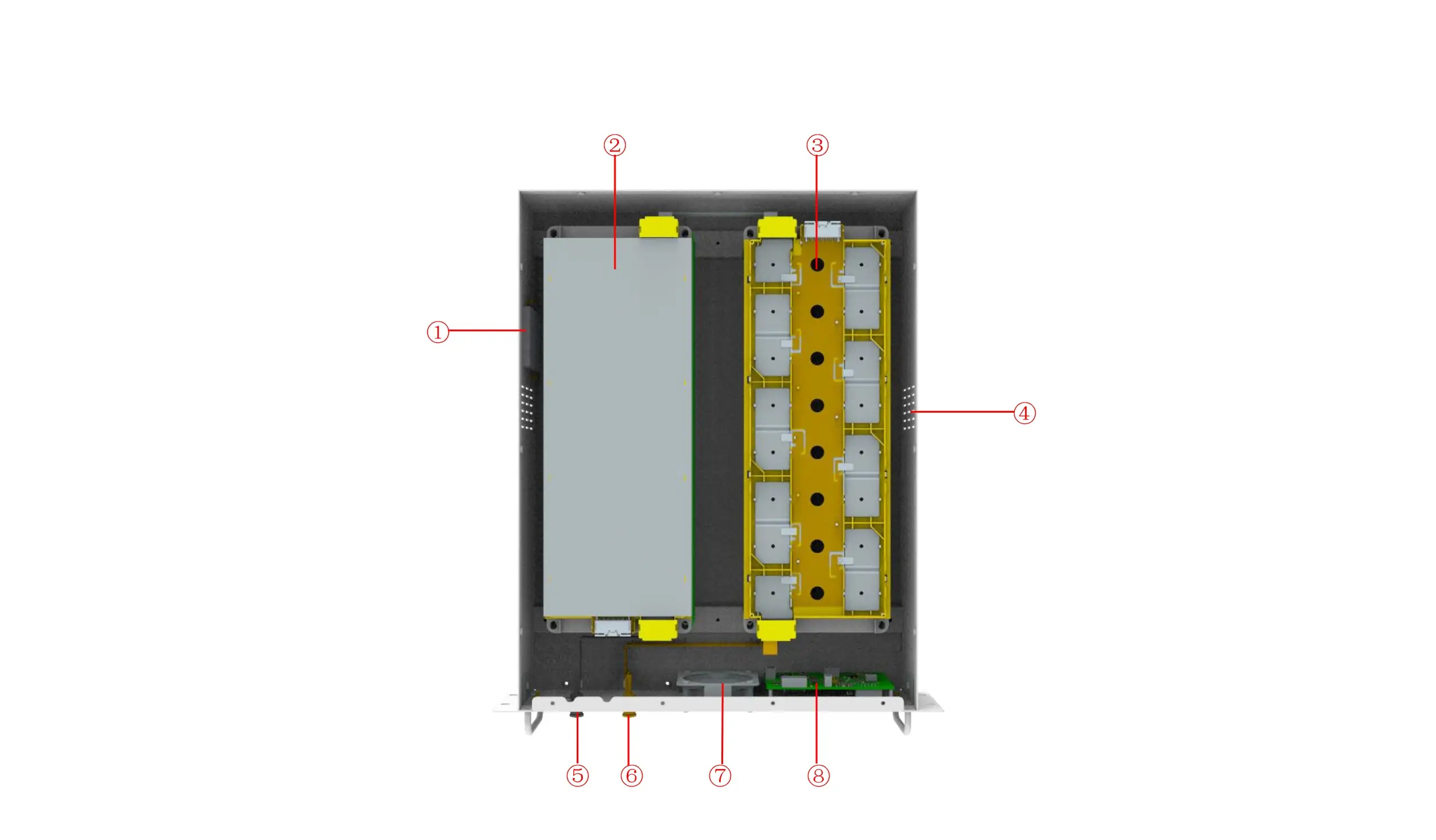

| ①Aerosol fire extinguishing device when |

n the pack is detected to be on fire, the aerosol is emitted to extinguish the fire |

| ②Battery module provides | s electrical energy storage and output |

| ③CCS | Cells Contact System |

| ④Air inlet cold | d air inlet |

| ⑤Battery negative- | / |

| ⑥Battery positive+ | / |

| ⑦Fan | Promote internal and external air flow |

| ⑧BMU | Battery monitoring |

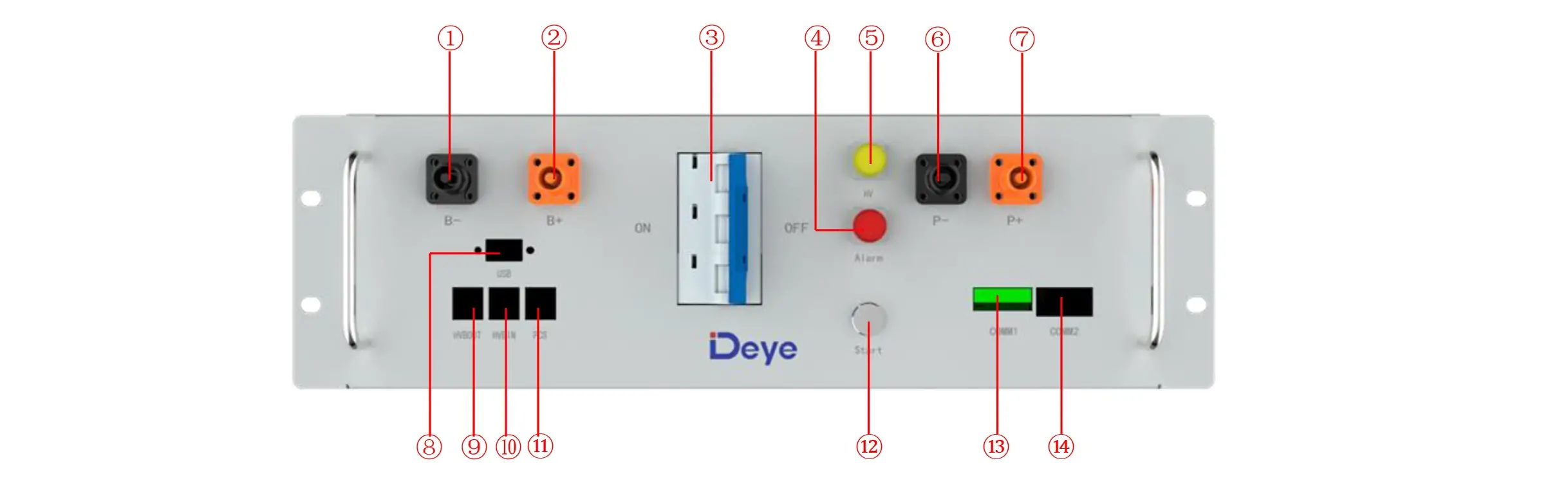

| ①B- | Connection position of the common negative pole of the battery |

| ②B+ | Connection position of the common positive pole of the battery |

| ③Air switch used | d to manually control the connection between the battery rack and external devices |

| ④ALRM light indicator | Battery system fault alarm indicator |

| ⑤HV light indicator | High-voltage hazard indicator |

| ⑥PCS- | Connection position of PCS negative pole |

| ⑦PCS+ | Connection position of PCS positive pole |

| ⑧USB | BMS upgrade interface and storage expansion interface |

| ⑨OUT COM | Connection position with next HVB-100A 750V communication output |

| ⑩IN COM | Connection position with previous HVB-100A750V communication input |

| ⑪PCS COM | Communication interface with charging and discharging equipment |

| ⑫START | A start switch of 12VDC power inside the high-voltage control box |

| ⑬COMM1 | Communicative connection with the cabinet |

| ⑭COMM2 |

Communicative connection with the first battery module; and providing 12VDC power for the first battery module. |