June 11, 2025, Shanghai — At the SNEC exhibition, Hithium officially unveiled the full results of the world's first open-door combustion test for its ∞Block 5MWh energy storage system during the "Leap Forward, Safety First" product safety technology seminar. The release included the complete test process, technical details, and authoritative data, alongside an on-site presentation of the large-scale fire test certification from global safety science leader UL Solutions.

Conducted under the strict methodologies of UL9540A and NFPA855 and witnessed by UL Solutions, certified U.S. fire engineers, and client representatives, the test pushed industry boundaries with four extreme conditions:

- Open-door combustion

- Dual 15cm clearance (minimum industry spacing)

- Deactivated active fire protection

- 100% state-of-charge (SOC)

Results confirmed all adjacent containers’ cell temperatures remained far below UL9540A's thermal runaway trigger threshold. The ignited module showed no structural deformation or collapse, and zero fire or thermal runaway propagation occurred in three neighboring units — demonstrating Hithium's breakthrough in 5MWh system safety.

Wang Hualei, the test project lead, presented background and video evidence detailing the rigorous procedure. UL Solutions’ APAC Energy & Automation GM Xiao Qifeng emphasized the test's unprecedented severity: "Unlike conventional ‘closed-door + explosion-relief’ methods, Hithium's open-door test simulates oxygen-rich conditions. Success without external fire intervention proves autonomous fire resistance and sets a critical reference for global safety standards."

Beyond open-door combustion, Hithium incorporated three additional extreme parameters:

1. 15cm spacing between containers — validating thermal runaway isolation under 1,300℃+ flames.

2. Disabled active fire systems — verifying passive design reliability without external aid.

3. 100% SOC — maximizing energy release to prove stability under worst-case scenarios.

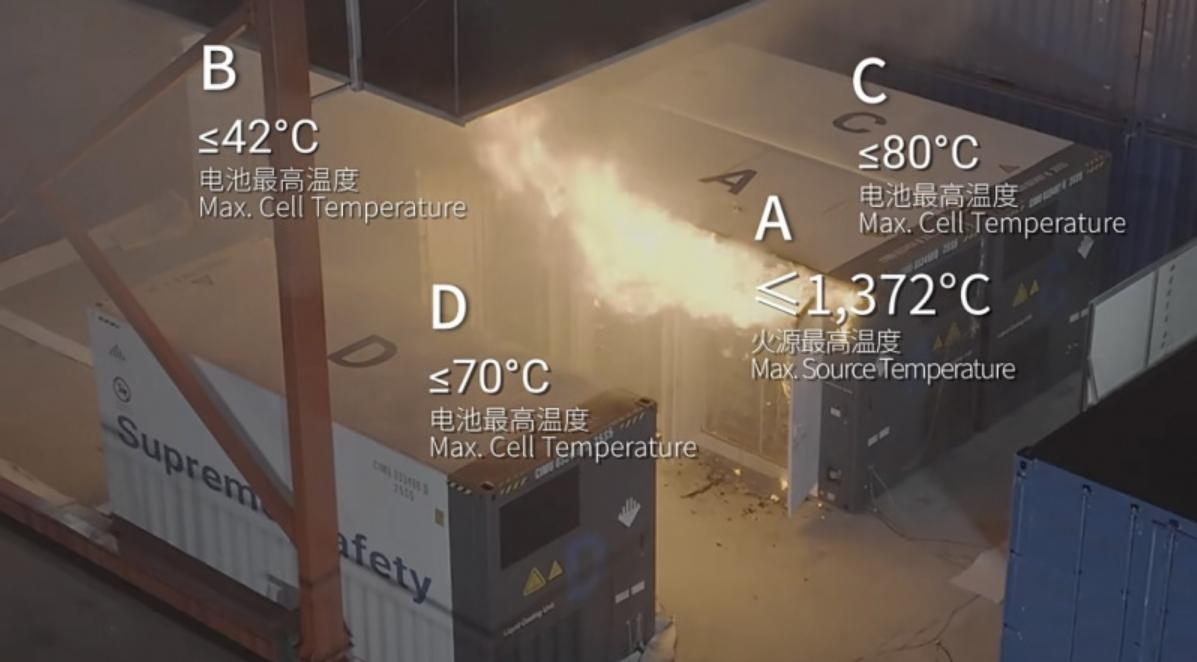

The test ignited eight cells in Module A, inducing thermal runaway and propagation. With doors open for full oxygen exposure, all battery packs fully combusted, maximizing heat transfer to adjacent Modules B, C, and D.

- Peak fire phase: Temperatures hit 1,372℃ at hour 4. Cell temperatures in adjacent units stayed far below thermal runaway thresholds (Module B ≤42℃; C ≤80℃; D ≤70℃).

- Sustained combustion: After 15 hours, flames extinguished naturally. Module A maintained structural integrity, with zero fire or thermal runaway spread to neighboring units. Modules B/C/D showed only surface damage; internal modules remained intact.

This success stems from Hithium's multi-level safety architecture:

- Cell level: High-thermal-stability materials, functional electrolyte additives, and heat-resistant separators.

- Module level: Thermal propagation barriers between cells and fire-resistant covers preventing oxygen ingress.

- System level: Specialized skeleton material maintaining strength below 600℃; structural enhancements preventing high-temperature collapse.

Safety anchors sustainable energy storage. Hithium's pioneering open-door test — conducted under extraordinary conditions — not only showcases its technical prowess but also underscores its commitment to transparency. This achievement provides critical insights for advancing global energy storage safety. Moving forward, Hithium will continue prioritizing safety to secure the green energy transition.

Previous:How Long Do LiFePO4 Batteries Last? A Deep Dive into 7 Key Factors Affecting Lifespan