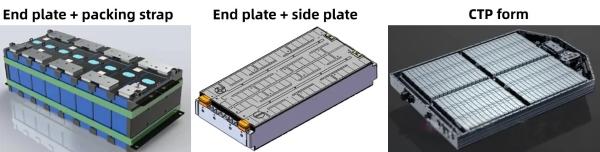

Square shell power battery modules generally come in the following configurations:

For the first type of module, the green part is the strapping – yes, the same kind of packing strap used for warehouse cardboard boxes. So the question is: Is this kind of strapping actually okay? Could it break? Why isn't it like the stainless steel bands used for fuel cells?

Enhance Structural Stability: Prevents the battery cells from shifting or getting damaged under external forces like vibration and impact. Furthermore, the busbar connections between cells are typically made of rigid aluminum, which cannot tolerate large deformations. The strapping ensures the structural strength and stability of the module.

Handle Cell Expansion: Square shell cells expand during charge and discharge cycles. The strapping restricts this expansion, preventing module deformation and reducing the impact of module expansion on the structural integrity of the PACK case. This improves battery performance and service life.

Improve Heat Dissipation: Keeps the cells in close contact, increasing the contact area, which is beneficial for battery thermal management.

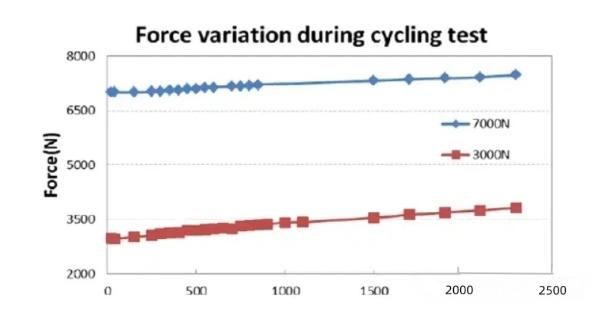

Based on experience, the initial assembly force is generally recommended to be between 100 kgf and 700 kgf. Some research has found that when the cell capacity is low, the expansion force is relatively mild. However, as shown in the chart below for a specific Lithium Iron Phosphate (LFP) battery, the cell expansion force increases sharply after the State of Charge (SOC) exceeds 80%. Interestingly, LFP is less sensitive to assembly force, a topic that gained more attention mainly after the rise of high-energy-density NMC (Nickel Manganese Cobalt) batteries for vehicles. The author couldn't find highly authoritative research literature on this, as it really depends on the cell form factor and the specific processes of different power battery manufacturers.

PET. This is a packaging material with good tensile strength and welding performance, capable of long-term operation between -50°C and 100°C. PET plastic steel strapping, particularly flame-retardant PET strapping, is the mainstream choice for lithium battery module bundling, holding about a 65% market share. PET plastic steel strapping, with a melting point as high as 260°C, dominates the market due to its excellent cost-performance ratio and lightweight advantages.

Additionally, the strapping must meet other requirements such as insulation, flame retardancy, and resistance to aging.

Next:HiTHIUM and El-Mor Partner on 1.5GWh Long-Duration Energy Storage Projects in Israel