HiTHIUM has successfully carried out the world’s first open-door large-scale fire test of its ∞Power 6.25MWh 4-hour long-duration energy storage (LDES) system, which utilizes kiloampere-hour (kAh) battery cells. The test was performed under the full oversight of representatives from UL Solutions, U.S. Authorities Having Jurisdiction, and Fire Protection Engineers, in strict accordance with the latest requirements of UL 9540A 2025 and NFPA 855-2026.

Results confirm that the high-energy-density 6.25MWh storage system, built with ultra-large-capacity cells, demonstrated stable and controllable safety performance under extreme conditions. This achievement represents a critical breakthrough in safety validation for LDES systems at higher energy levels, reinforcing the safety foundation needed for large-scale industry deployment.

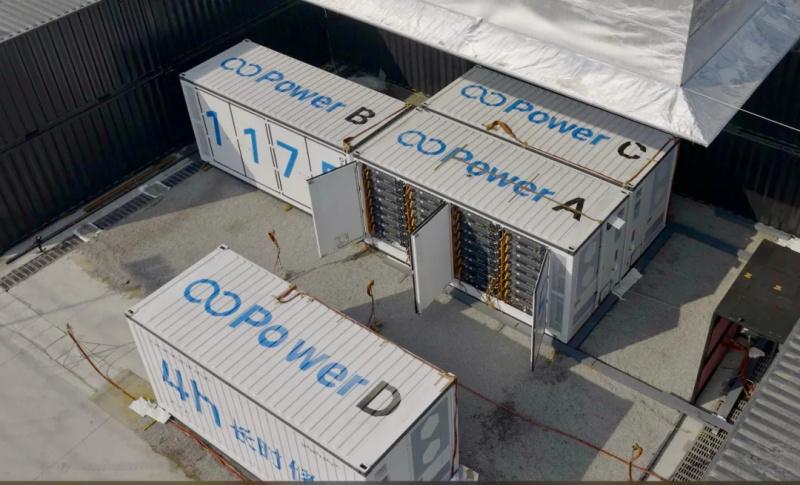

Following its earlier open-door fire test on a 5MWh system, HiTHIUM advanced its validation efforts by focusing on the ∞Power 6.25MWh LDES system and its core ∞Cell 1175Ah, verifying system-level safety under significantly higher energy conditions.

The test was conducted under stringent parameters: container doors remained fully open throughout, creating an “open-door combustion” scenario that maximized oxygen supply and flame exposure; adjacent containers were positioned back-to-back and side-by-side with only 15 cm spacing; the system was tested at 100% state of charge; and all active fire suppression systems were disabled, relying entirely on the system’s intrinsic safety design.

To address the compounded risks presented by ultra-large-capacity cells and high-energy-density systems, HiTHIUM employed a multi-layer safety architecture spanning cell, module, and system levels. Guided by the technical principle of “release, protection, and resistance,” the test addressed three core safety challenges:

- Release Without Explosion: Controlled Management of Ultra-High Energy Release

To manage the substantial energy release during thermal runaway of the 1175Ah cells, HiTHIUM implemented a three-dimensional airflow channel with directional venting, while the module adopted a dual pressure relief valve design. This enabled rapid yet controlled gas release at both cell and module levels, preventing explosive pressure buildup. No explosions or debris ejection occurred during the test.

- Combustion Without Propagation: Dual Physical Barriers Against Thermal Spread

Under severe open-door combustion and minimal spacing conditions, the system withstood direct flame exposure and intense heat transfer. Fire-resistant module covers, reinforced steel enclosures, and insulated multi-layer container structures successfully confined the fire to a single battery system. There was no thermal propagation to adjacent containers, and temperatures in neighboring cells stayed within safe limits.

- Resistance Without Structural Failure: Stability Under Extreme Thermal Stress

To endure prolonged high-temperature exposure, the ∞Power 6.25MWh system was reinforced with a high-strength steel frame, stiffeners, and dual-layer partitions. Following continuous combustion, the affected container remained structurally intact, with no significant deformation or collapse observed.

This test systematically validated the overall safety performance of the ∞Power 6.25MWh LDES system equipped with kAh battery cells, marking a milestone within the global energy storage safety validation framework.

As system capacities advance from 5MWh to 6.25MWh, HiTHIUM continues to prioritize safety and reliability through rigorous design standards and extreme-condition testing.

Looking forward, HiTHIUM will maintain its strategic focus on LDES, further strengthening safety foundations and core technologies. By contributing to the development of higher global safety standards for energy storage and collaborating closely with industry partners, HiTHIUM aims to propel LDES toward larger scale, greater reliability, and safer, more efficient deployment—supporting a steady and sustainable global energy transition.

Next:None

Previous:How to Store NiMH Batteries Safely for Maximum Lifespan and Performance: An Ultimate Guide