Driven by widespread adoption in energy storage systems and new energy vehicles, lithium iron phosphate (LiFePO₄) batteries are becoming a mainstream choice due to their exceptional safety, superior cycle life, and cost-effectiveness. However, battery lifespan is not fixed; its degradation rate is closely tied to charging/discharging strategies. This article analyzes four typical charging methods from perspectives of longevity, capacity retention, and aging mechanisms, providing theoretical and practical insights for BMS optimization and battery system design.

Definition:

Charging to a low SOC range (e.g., 30%–70%) while limiting depth of discharge (DOD) to shallow levels (e.g., 20%–50%).

Key Impacts:

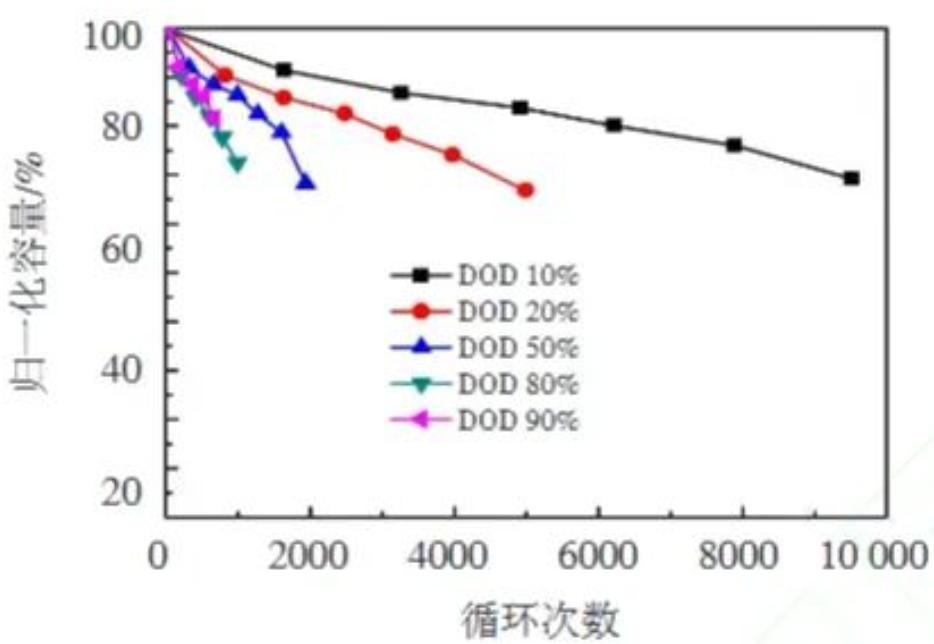

- Significantly extends lifespan: Studies show cycles can exceed tens of thousands when DOD ≤20%, far outperforming high-DOD strategies.

- Reduces structural stress: Avoids repeated expansion/contraction of electrodes, minimizing SEI film damage and reformation.

- Slows side reactions: Lower SOC suppresses electrolyte decomposition and lithium loss.

Ideal For:

Longevity-critical applications: residential solar storage, grid-scale ESS, and second-life battery systems.

Definition:

Charging to 100% SOC and discharging to the lower voltage limit (e.g., 2.5V), utilizing full capacity per cycle.

Key Impacts:

- Accelerates degradation: High SOC storage intensifies side reactions (e.g., electrolyte oxidation), causing 2–3× higher capacity loss vs. 60% SOC.

- Induces mechanical fatigue: Deep discharge triggers anode/cathode lattice stress, promoting SEI cracks and lithium dendrites.

- Shortens cycle life: At 90% DOD, lifespan is typically 40%–50% shorter than partial cycling.

Ideal For:

Emergency power or high-capacity scenarios (e.g., backup systems), but strictly limit frequency.

Definition:

Charging to 100% SOC but discharging partially (e.g., to 70% SOC, DOD=30%).

Key Impacts:

- High-SOC damage dominates: Sustained high voltage thickens SEI film, increases impedance, and hastens capacity fade—even with shallow discharge.

- Poor low-temperature performance: Severe anode polarization at high SOC reduces discharge voltage stability.

- Tolerable short-term only: Suitable for brief high-power bursts but unsustainable for long-term use.

Ideal For:

Short-duration, high-power needs (e.g., drone takeoffs, traction equipment), avoid prolonged high SOC.

Definition:

Maintaining fixed power during charge/discharge by dynamically adjusting current based on voltage.

Key Impacts:

- Mirrors real-world loads: Aligns with dynamic demands in grid dispatch, UPS, and industrial ESS better than constant-current methods.

- Lower rate capability: Voltage-dependent current reduces high-rate capacity retention vs. constant-current cycling.

- Optimization benchmark: Provides accurate field-performance data for strategy refinement.

Ideal For:

High-fluctuation environments: telecom base stations, data centers, and commercial ESS.

Based on empirical data, these strategies optimize LiFePO₄ lifespan:

- Primary strategy: Partial cycling (30%–70% SOC) for high-cycling, long-life applications.

- Storage protocol: Maintain ≈60% SOC; reduce to 40% in high-temperature environments.

- Full-depth cycling: Restrict frequency and recalibrate BMS regularly to prevent SOC drift.

- Testing upgrade: Adopt constant-power testing standards to reflect real-world behavior.

Economic and sustainable battery use hinges on strategic charging. Partial cycling trades marginal capacity for multi-fold lifespan extension—delivering the highest ROI. As BMS and AI-driven predictive systems evolve, charging management will become more precise. Choosing the right strategy isn't just about "battery health"; it's the key to minimizing total cost of ownership (TCO).

Previous:EVE Energy Announces Plans to Launch All-Solid-State Batteries in 2026!