Depth of Discharge (DoD) refers to the percentage of a battery's total capacity that has been consumed during use. This metric is critical for evaluating the performance and longevity of lithium-ion batteries, especially in high-demand applications. In industrial environments, deeper discharges accelerate battery degradation, while maintaining shallow discharges enhances efficiency and extends lifespan. Industries such as medical technology, robotics, security systems, and infrastructure projects rely on precise DoD management to ensure operational reliability and cost-effectiveness. A thorough understanding of DoD is essential for maintaining consistent performance in these sectors.

-Optimal DoD Range: Maintaining DoD between 20% and 80% minimizes stress on battery components, extending cycle life.

-Battery Management Systems (BMS): Implement BMS to monitor and control DoD, preventing over-discharge and enhancing reliability.

-Partial Charging: Frequent partial charging reduces electrode strain and heat generation, improving long-term battery health.

1.1 What is Depth of Discharge (DoD)?

DoD quantifies the proportion of a battery's capacity used relative to its maximum capacity. For example, a 100Ah battery discharging 40Ah has a 40% DoD. The formula for calculating DoD is:

DoD (%) = (Capacity Used / Total Capacity) × 100

This metric is vital for industries dependent on lithium-ion batteries, such as medical devices and robotics, where consistent performance is non-negotiable. Deep-cycle batteries, such as LiFePO4 variants, tolerate higher DoD levels better than standard lithium-ion batteries. However, higher DoD levels generally accelerate degradation, necessitating careful management.

1.2 Impact of DoD on Battery Lifespan and Performance

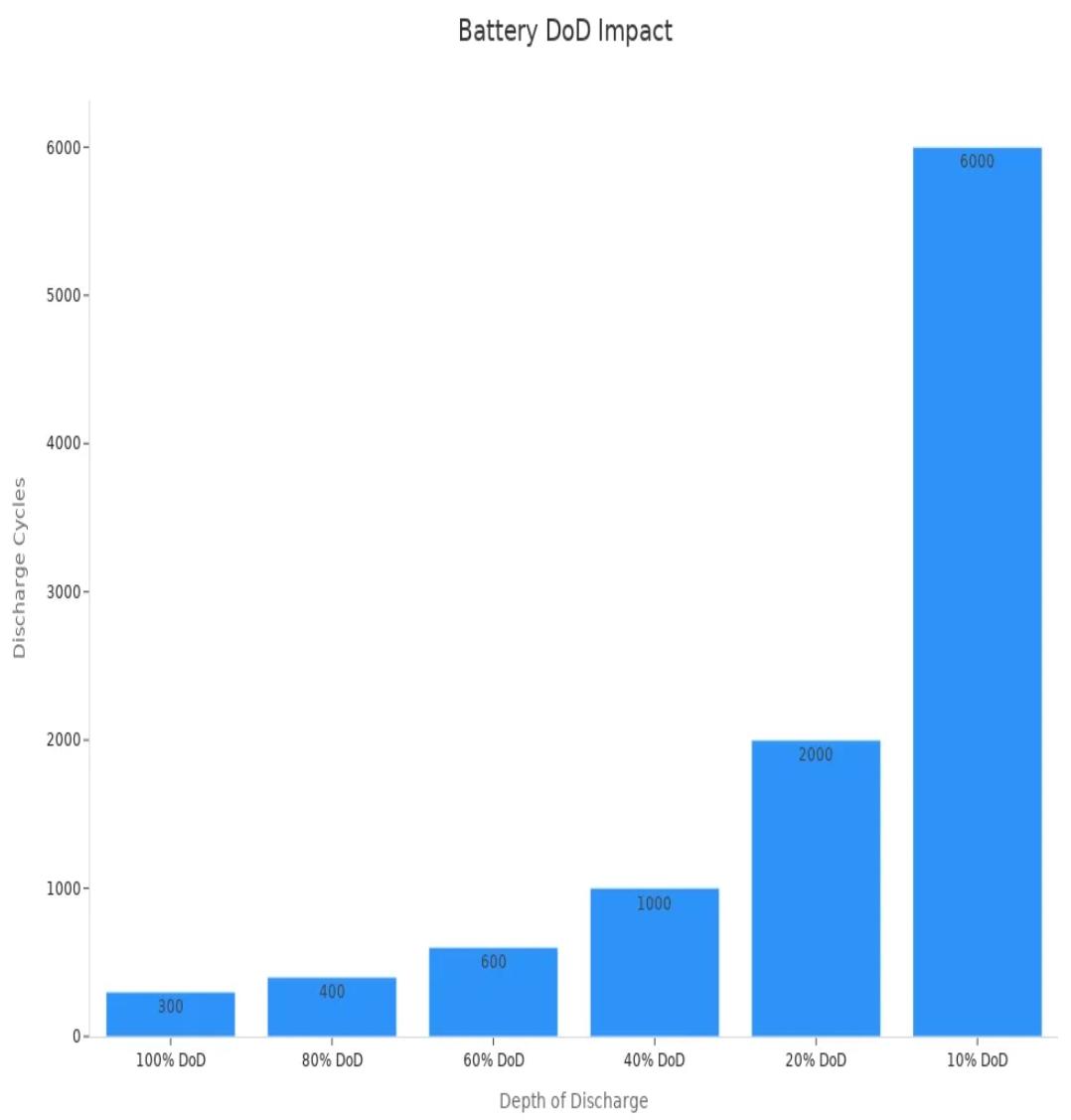

DoD directly influences battery lifespan and efficiency. Higher DoD levels degrade internal components (e.g., cathodes and electrolytes), leading to reduced capacity, increased internal resistance, and shorter cycle life. Studies indicate:

Depth of Discharge | Cycle Life (Approx.) |

100% DoD | ~300 cycles |

80% DoD | ~400 cycles |

60% DoD | ~600 cycles |

40% DoD | ~1,000 cycles |

20% DoD | ~2,000 cycles |

10% DoD | ~6,000 cycles |

Deep discharges also generate excess heat due to heightened internal resistance, compromising thermal stability. This is particularly critical in industrial automation and energy storage systems. Limiting DoD optimizes performance and mitigates premature failure risks.

1.3 Shallow vs. Deep Discharge: A Comparative Analysis

Parameter | Shallow Discharge | Deep Discharge |

Cycle Life | Longer | Shorter |

Heat Generation | Minimal | Significant |

Performance Stability | Consistent | Degrades over time |

Applications | Medical devices, robotics | Energy storage, industrial systems |

Shallow discharges are ideal for applications requiring frequent cycling (e.g., robotics), whereas deep discharges suit energy-intensive systems. Effective DoD management balances energy output with longevity.

2.1 Setting Optimal Discharge Limits

For most lithium-ion batteries, maintaining DoD between 20% and 80% strikes a balance between usability and longevity. In industrial applications like robotics, precise discharge limits enforced by BMS ensure reliability.

Tip: Tailor discharge limits to application needs. Medical devices may require stricter limits than energy storage systems.

2.2 Benefits of Partial Charging

Frequent partial charging reduces electrode stress and heat buildup. Research involving 300 battery samples demonstrated that partial cycles preserve capacity and extend cycle life. BMS integration enables real-time monitoring to implement this strategy effectively.

2.3 Avoiding Over-Discharge

Over-discharge (voltage dropping below safe thresholds) causes irreversible damage, including capacity loss and safety risks. Mitigation strategies include:

-BMS Alarms: Set automatic cutoffs at minimum voltage thresholds.

-Regular Inspections: Check for swelling or performance decline.

-Prioritize LiFePO4 Batteries: These tolerate deeper discharges but still require vigilant management.

3.1 Core Functions of BMS

BMS monitors critical parameters (voltage, current, temperature) to prevent over-discharge and ensure balanced cell performance. Key features:

-State of Charge (SOC) Tracking: Prevents overcharging/discharging.

-Voltage Regulation: Avoids deep discharges.

-Thermal Management: Mitigates efficiency losses from temperature fluctuations.

3.2 Advanced BMS Capabilities

Modern BMS leverage AI and machine learning for predictive maintenance. For example, industrial BMS achieve a root mean square error (RMSE) of 0.01173 in predicting battery lifespan, enabling timely interventions to reduce downtime.

3.3 Industry-Specific Applications

-Electric Vehicles: BMS ensures thermal stability in high-energy-density batteries (e.g., NMC, LMO).

-Robotics: Enables uninterrupted energy delivery for automated systems.

-Infrastructure: Regulates energy use in critical applications like grid storage.

Effective DoD management is pivotal for maximizing lithium battery performance. Research by the Electric Power Research Institute indicates poor DoD management can halve battery lifespan. Adopting practices like partial charging and BMS integration enhances reliability, reduces capacity loss, and extends cycle life—critical for industries where consistent energy output is paramount.